ABOUT US

FALGAGEN IS A FRENCH COMPANY PROVIDING SERVICES IN R&D, MANUFACTURING, MARKETING & CORPORATE SUPPORT

Located in the heart of the “HA Valley, we have gathered a team of seasoned experts in Hyaluronan and biopolymers (Chitosan, glycosaminoglycans, etc), aiming to accompany our clients from research to market.

THE INNOVATION BOOSTERS

Our team of experts, composed of experienced engineers, constantly seeks to challenge the status quo. They possess in-depth and specialized knowledge in the field of Hyaluronic Acid and have a unique ability to solve complex problems and make informed decisions.

WE AIM AT PUSHING THE BOUNDARIES OF INNOVATION THROUGH THE VIRTUES OF HYALURONIC ACID.

ABOUT US

FALGAGEN IS A FRENCH COMPANY PROVIDING SERVICES IN R&D, MANUFACTURING, MARKETING & CORPORATE SUPPORT

Located in the heart of the “HA Valley, we have gathered a team of seasoned experts in Hyaluronan and biopolymers (Chitosan, glycosaminoglycans, etc), aiming to accompany our clients from research to market.

THE INNOVATION BOOSTERS

Our team of experts, composed of experienced engineers, constantly seeks to challenge the status quo. They possess in-depth and specialized knowledge in the field of Hyaluronic Acid and have a unique ability to solve complex problems and make informed decisions.

WE AIM AT PUSHING THE BOUNDARIES OF INNOVATION THROUGH THE VIRTUES OF HYALURONIC ACID.

ABOUT US

FALGAGEN IS A FRENCH COMPANY PROVIDING SERVICES IN R&D, MANUFACTURING, MARKETING & CORPORATE SUPPORT

Located in the heart of the “HA Valley, we have gathered a team of seasoned experts in Hyaluronan and biopolymers (Chitosan, glycosaminoglycans, etc), aiming to accompany our clients from research to market.

THE INNOVATION BOOSTERS

Our team of experts, composed of experienced engineers, constantly seeks to challenge the status quo. They possess in-depth and specialized knowledge in the field of Hyaluronic Acid and have a unique ability to solve complex problems and make informed decisions.

FALGAGEN CONSULTING & SERVICES PROVIDES TAILORED GUIDANCE AT EVERY CRITICAL STAGE OF THE LIFE CYCLE MANAGEMENT, LEADING TO SUCCESSFUL AND SUSTAINABLE PRODUCT LAUNCHES IN THE MARKET.

R&D

WE ARE DEVELOPING THE NEXT GENERATION PRODUCTS BY IMPROVING EXISTING FORMULATIONS OR CONCEIVING INNOVATIVE SOLUTIONS TAILORED TO THE NEEDS OF OUR CLIENTS.

FORMULATION CONCEPTION : BUILD UP YOUR PRODUCTS RANGE

- Based on your request, we design formulation and process from product’s concept to prototypes.

- Our expertise enables the formulation of solutions or gels: Non-crosslinked, Crosslinked (monophasic), Crosslinked (biphasic), Combined (anaesthetics, polymers, antioxidant, etc)

- We process all manufacturing steps in our laboratory in Annecy, from raw material solubilisation to final sterilisation of syringes.

FORMULATION REDESIGN : IMPROVE YOUR PRODUCTS PROPERTIES

Based on a current formulation, we redesign formulation and process in order to improve product’s properties

ANALYTICAL TESTS : UNDERSTAND YOUR PRODUCTS PROPERTIES

- We perform analytical services on solutions and gels in our laboratory: Control → pH, Osmolarity // Injectability with Ejection forces // Rheological measurements: Determination of the LVED → linear ViscoElastic Domain; Determination of the viscoelastic properties → G’, G”, tanẟ, crossover frequency or even strength and stretch score; Determination of the viscosity → zero-shear viscosity or viscosity at fixed shear rate; Compression tests; Resistance to enzymatic or free-radicals degradation; Evolution of the impact of temperature on the rheological properties

- We also partner with a network of external laboratories, used to analyse hyaluronan based solutions for: Components dosage, Crosslinking results, etc

BIOCOMPATIBILITY & CLINICALS COORDINATION : ACCOMPANY YOUR PRODUCT TO MARKET

We accompany you in the identification of qualified partners who aim at preparing the regulatory dossier: Products Stability Studies Follow-up, Biocompatibility tests, Clinical trials

MANUFACTURING SERVICES

WE SUPPORT OUR CLIENTS FROM THE SET-UP OR OPTIMIZATION OF A PRODUCTION SITE TO PRODUCT VALIDATION THROUGH THE DEVELOPMENT OF A DEDICATED MANUFACTURING PROCESS.

MANUFACTURING SITE SET-UP: PREPARE YOUR SITE FOR MANUFACTURING

Based on your sales forecasts, we help you to set-up your manufacturing site with the adapted organisation :

- Plant and clean room sizing and layout mapping

- Clean room classification according to each manufacturing step

- Optimisation of the material and operators flows

- Mapping of the equipment locations

- Equipment manufacturers recommendations

CMO QUALIFICATION : SUBCONTRACT YOUR MANUFACTURING

Based on your manufacturing strategy, we we guide you in qualifying and selecting the ideal manufacturing subcontractor (CMO) for your products using specific criteria:

- Manufacturing capacity

- Technological process knowledge and experience

- Health authorities’ certifications

- Quantities flexibility

- Reputation

INDUSTRIALISATION : INDUSTRIALISE YOUR PRODUCT

- When designing a formulation, we always start to think about the industrial process to ensure its scalability. We follow a specific industrialisation pathway which has proven efficiency through

- Pilot manufacturing : We ensure an intermediate upscale in our facility in Annecy to finetune manufacturing parameters

- Development manufacturing : We ensure the integration of the manufacturing in your facility or at the CMO, and follows until the operators master the process until the validation.

- Know how transmission : We provide theoretical transmission through learning modules to engineers and operators and operational transmission through hands on approach in clean room during development manufacturing.

PROCESS & SITE OPTIMISATION : OPTIMISE MANUFACTURING EFFICIENCY

Through our extensive industrial experience, we perform industrial audits

Identification of the gaps / improvement areas

- Manufacturing documents

- Manufacturing site organisation (clean rooms, flows,…)

- Equipment in place

- Manufacturing process

- Operators’ manipulations

Optimisation advices

- Robustness / batch-to-batch consistency and repeatability

- Yield

- Capacity / Scale-up

- Ergonomics

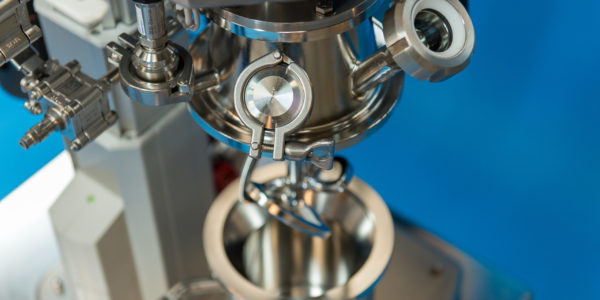

Equipment design & manufacturing

For all synthesis steps, we design and manufacture through our affiliated company Vortex, customised industrial equipment tailored to your needs.

PROCESS AUTOMATISATION : AUTOMATISE YOUR PROCESS

We have developed a unique expertise on the full automatization of the synthesis steps (from solubilisation of raw materials until obtaining a bulk gel ready to fill in syringes).

We have the capacity to automatise existing complex processes by respecting the manufacturing flowchart.

The advantages of automatising synthesis steps:

- Reduce gel losses during process

- Improve batch-to-batch repeatability

- Increase the manufacturing capacity without clean room extension (only a few squared meters)

- Reduce the number of operators

- Keep process confidentiality

INDUSTRIALIZATION : EQUIPMENT

WE ACCOMPANY OUR CUSTOMERS WITH THE OBJECTIVE TO OPTIMISE INDUSTRIAL OPERATIONS, TO INCREASE MANUFACTURING CAPACITY, PROCESS YIELD AND PROCESS ROBUSTNESS THANKS TO OUR RECENT ACQUISITION OF VORTEX, A LEADING EXPERT IN CUSTOMIZED INDUSTRIAL EQUIPMENT.

- Equipment audit: equipment review, equipment evaluation;

- Equipment recommendations: Definition of equipment needs according to commercial & industrial plans, recommendation of equipment references and equipment manufacturers;

- Equipment Design & Development: customized equipment integrated in your process, full automatization of all the synthesis steps (from solubilization to a bulk gel ready to be filled in syringes up to 25-30L batches).

MARKETING

WE SUPPORT IN VARIOUS MARKETING ACTIVITIES THROUGH YOUR PRODUCT’S LIFECYCLE:

- Strategic Insights : We take part to Advisory Boards to draw market trends, share market knowledge

- Competitive Screening : We can perform an independent evaluation of the competitive products, both on their properties but also on their positioning.

- Strategic Marketing : We support in the preparation of marketing plans, product management, positioning strategy.

- Operational Marketing : We support launch plans and activities, marketing tools, sales support creation, events management, team training and building.

- Marketing audit : We review your marketing activities and tools and provide recommendations.

CORPORATE SUPPORT SERVICES

WE GUIDE OUR CLIENTS AND PROVIDE STRATEGIC SUPPORT TO FACILITATE MARKET ENTRY AND ACCELERATE GROWTH THROUGH DUE DILIGENCE, LICENSING, AND STRATEGIC ANALYSIS.

M&A DUE DILIGENCES : ACQUIRE OR SELL A BUSINESS

We provide technological & strategic due diligence for acquirers (BA, VC, PE, Family offices) and to sellers (entrepreneurs) ahead of a transaction closing. We perform onsite due diligences and provide you with a report (red flag or detailed) with recommendations, and eventual future investments estimations.

- Marketing : Positioning in its market, portfolio analysis, competitivity

- Manufacturing : Manufacturing site, Equipment, Process, Formulation / Technology

« FAST-TRACK » HYALURONAN TRAINIG : MAKE YOUR TEAM OPERATIONAL QUICKLY

We provide a fast-track training to new managers and leaders (C-levels, top management) entering in the hyaluronan industry, to enable a faster on-boarding. The Fast Track Hyaluronan Training aims to provide them with essential and comprehensive knowledge of hyaluronan.

FALGAGEN CONSULTING & SERVICES PROVIDES TAILORED GUIDANCE AT EVERY CRITICAL STAGE OF THE LIFE CYCLE MANAGEMENT, LEADING TO SUCCESSFUL AND SUSTAINABLE PRODUCT LAUNCHES IN THE MARKET.

R&D

WE ARE DEVELOPING THE NEXT GENERATION PRODUCTS BY IMPROVING EXISTING FORMULATIONS OR CONCEIVING INNOVATIVE SOLUTIONS TAILORED TO THE NEEDS OF OUR CLIENTS.

FORMULATION CONCEPTION : BUILD UP YOUR PRODUCTS RANGE

- Based on your request, we design formulation and process from product’s concept to prototypes.

- Our expertise enables the formulation of solutions or gels: Non-crosslinked, Crosslinked (monophasic), Crosslinked (biphasic), Combined (anaesthetics, polymers, antioxidant, etc)

- We process all manufacturing steps in our laboratory in Annecy, from raw material solubilisation to final sterilisation of syringes.

FORMULATION REDESIGN : IMPROVE YOUR PRODUCTS PROPERTIES

Based on a current formulation, we redesign formulation and process in order to improve product’s properties

ANALYTICAL TESTS : UNDERSTAND YOUR PRODUCTS PROPERTIES

- We perform analytical services on solutions and gels in our laboratory: Control → pH, Osmolarity // Injectability with Ejection forces // Rheological measurements: Determination of the LVED → linear ViscoElastic Domain; Determination of the viscoelastic properties → G’, G”, tanẟ, crossover frequency or even strength and stretch score; Determination of the viscosity → zero-shear viscosity or viscosity at fixed shear rate; Compression tests; Resistance to enzymatic or free-radicals degradation; Evolution of the impact of temperature on the rheological properties

- We also partner with a network of external laboratories, used to analyse hyaluronan based solutions for: Components dosage, Crosslinking results, etc

BIOCOMPATIBILITY & CLINICALS COORDINATION : ACCOMPANY YOUR PRODUCT TO MARKET

We accompany you in the identification of qualified partners who aim at preparing the regulatory dossier: Products Stability Studies Follow-up, Biocompatibility tests, Clinical trials

MANUFACTURING SERVICES

WE SUPPORT OUR CLIENTS FROM THE SET-UP OR OPTIMIZATION OF A PRODUCTION SITE TO PRODUCT VALIDATION THROUGH THE DEVELOPMENT OF A DEDICATED MANUFACTURING PROCESS.

MANUFACTURING SITE SET-UP: PREPARE YOUR SITE FOR MANUFACTURING

Based on your sales forecasts, we help you to set-up your manufacturing site with the adapted organisation :

- Plant and clean room sizing and layout mapping

- Clean room classification according to each manufacturing step

- Optimisation of the material and operators flows

- Mapping of the equipment locations

- Equipment manufacturers recommendations

CMO QUALIFICATION : SUBCONTRACT YOUR MANUFACTURING

Based on your manufacturing strategy, we we guide you in qualifying and selecting the ideal manufacturing subcontractor (CMO) for your products using specific criteria:

- Manufacturing capacity

- Technological process knowledge and experience

- Health authorities’ certifications

- Quantities flexibility

- Reputation

INDUSTRIALISATION : INDUSTRIALISE YOUR PRODUCT

- When designing a formulation, we always start to think about the industrial process to ensure its scalability. We follow a specific industrialisation pathway which has proven efficiency through

- Pilot manufacturing : We ensure an intermediate upscale in our facility in Annecy to finetune manufacturing parameters

- Development manufacturing : We ensure the integration of the manufacturing in your facility or at the CMO, and follows until the operators master the process until the validation.

- Know how transmission : We provide theoretical transmission through learning modules to engineers and operators and operational transmission through hands on approach in clean room during development manufacturing.

PROCESS & SITE OPTIMISATION : OPTIMISE MANUFACTURING EFFICIENCY

Through our extensive industrial experience, we perform industrial audits

Identification of the gaps / improvement areas

- Manufacturing documents

- Manufacturing site organisation (clean rooms, flows,…)

- Equipment in place

- Manufacturing process

- Operators’ manipulations

Optimisation advices

- Robustness / batch-to-batch consistency and repeatability

- Yield

- Capacity / Scale-up

- Ergonomics

Equipment design & manufacturing

For all synthesis steps, we design and manufacture through our affiliated company Vortex, customised industrial equipment tailored to your needs.

PROCESS AUTOMATISATION : AUTOMATISE YOUR PROCESS

We have developed a unique expertise on the full automatization of the synthesis steps (from solubilisation of raw materials until obtaining a bulk gel ready to fill in syringes).

We have the capacity to automatise existing complex processes by respecting the manufacturing flowchart.

The advantages of automatising synthesis steps:

- Reduce gel losses during process

- Improve batch-to-batch repeatability

- Increase the manufacturing capacity without clean room extension (only a few squared meters)

- Reduce the number of operators

- Keep process confidentiality

INDUSTRIALIZATION : EQUIPMENT

WE ACCOMPANY OUR CUSTOMERS WITH THE OBJECTIVE TO OPTIMISE INDUSTRIAL OPERATIONS, TO INCREASE MANUFACTURING CAPACITY, PROCESS YIELD AND PROCESS ROBUSTNESS THANKS TO OUR RECENT ACQUISITION OF VORTEX, A LEADING EXPERT IN CUSTOMIZED INDUSTRIAL EQUIPMENT.

- Equipment audit: equipment review, equipment evaluation;

- Equipment recommendations: Definition of equipment needs according to commercial & industrial plans, recommendation of equipment references and equipment manufacturers;

- Equipment Design & Development: customized equipment integrated in your process, full automatization of all the synthesis steps (from solubilization to a bulk gel ready to be filled in syringes up to 25-30L batches).

MARKETING

WE SUPPORT IN VARIOUS MARKETING ACTIVITIES THROUGH YOUR PRODUCT’S LIFECYCLE:

- Strategic Insights : We take part to Advisory Boards to draw market trends, share market knowledge

- Competitive Screening : We can perform an independent evaluation of the competitive products, both on their properties but also on their positioning.

- Strategic Marketing : We support in the preparation of marketing plans, product management, positioning strategy.

- Operational Marketing : We support launch plans and activities, marketing tools, sales support creation, events management, team training and building.

- Marketing audit : We review your marketing activities and tools and provide recommendations.

CORPORATE SUPPORT SERVICES

WE GUIDE OUR CLIENTS AND PROVIDE STRATEGIC SUPPORT TO FACILITATE MARKET ENTRY AND ACCELERATE GROWTH THROUGH DUE DILIGENCE, LICENSING, AND STRATEGIC ANALYSIS.

M&A DUE DILIGENCES : ACQUIRE OR SELL A BUSINESS

We provide technological & strategic due diligence for acquirers (BA, VC, PE, Family offices) and to sellers (entrepreneurs) ahead of a transaction closing. We perform onsite due diligences and provide you with a report (red flag or detailed) with recommendations, and eventual future investments estimations.

- Marketing : Positioning in its market, portfolio analysis, competitivity

- Manufacturing : Manufacturing site, Equipment, Process, Formulation / Technology

« FAST-TRACK » HYALURONAN TRAINIG : MAKE YOUR TEAM OPERATIONAL QUICKLY

We provide a fast-track training to new managers and leaders (C-levels, top management) entering in the hyaluronan industry, to enable a faster on-boarding. The Fast Track Hyaluronan Training aims to provide them with essential and comprehensive knowledge of hyaluronan.

FALGAGEN CONSULTING & SERVICES PROVIDES TAILORED GUIDANCE AT EVERY CRITICAL STAGE OF THE LIFE CYCLE MANAGEMENT, LEADING TO SUCCESSFUL AND SUSTAINABLE PRODUCT LAUNCHES IN THE MARKET.

R&D

WE ARE DEVELOPING THE NEXT GENERATION PRODUCTS BY IMPROVING EXISTING FORMULATIONS OR CONCEIVING INNOVATIVE SOLUTIONS TAILORED TO THE NEEDS OF OUR CLIENTS.

FORMULATION CONCEPTION : BUILD UP YOUR PRODUCTS RANGE

- Based on your request, we design formulation and process from product’s concept to prototypes.

- Our expertise enables the formulation of solutions or gels: Non-crosslinked, Crosslinked (monophasic), Crosslinked (biphasic), Combined (anaesthetics, polymers, antioxidant, etc)

- We process all manufacturing steps in our laboratory in Annecy, from raw material solubilisation to final sterilisation of syringes.

FORMULATION REDESIGN : IMPROVE YOUR PRODUCTS PROPERTIES

Based on a current formulation, we redesign formulation and process in order to improve product’s properties

ANALYTICAL TESTS : UNDERSTAND YOUR PRODUCTS PROPERTIES

- We perform analytical services on solutions and gels in our laboratory: Control → pH, Osmolarity // Injectability with Ejection forces // Rheological measurements: Determination of the LVED → linear ViscoElastic Domain; Determination of the viscoelastic properties → G’, G”, tanẟ, crossover frequency or even strength and stretch score; Determination of the viscosity → zero-shear viscosity or viscosity at fixed shear rate; Compression tests; Resistance to enzymatic or free-radicals degradation; Evolution of the impact of temperature on the rheological properties

- We also partner with a network of external laboratories, used to analyse hyaluronan based solutions for: Components dosage, Crosslinking results, etc

BIOCOMPATIBILITY & CLINICALS COORDINATION : ACCOMPANY YOUR PRODUCT TO MARKET

We accompany you in the identification of qualified partners who aim at preparing the regulatory dossier: Products Stability Studies Follow-up, Biocompatibility tests, Clinical trials

MANUFACTURING SERVICES

WE SUPPORT OUR CLIENTS FROM THE SET-UP OR OPTIMIZATION OF A PRODUCTION SITE TO PRODUCT VALIDATION THROUGH THE DEVELOPMENT OF A DEDICATED MANUFACTURING PROCESS.

MANUFACTURING SITE SET-UP: PREPARE YOUR SITE FOR MANUFACTURING

Based on your sales forecasts, we help you to set-up your manufacturing site with the adapted organisation :

- Plant and clean room sizing and layout mapping

- Clean room classification according to each manufacturing step

- Optimisation of the material and operators flows

- Mapping of the equipment locations

- Equipment manufacturers recommendations

CMO QUALIFICATION : SUBCONTRACT YOUR MANUFACTURING

Based on your manufacturing strategy, we we guide you in qualifying and selecting the ideal manufacturing subcontractor (CMO) for your products using specific criteria:

- Manufacturing capacity

- Technological process knowledge and experience

- Health authorities’ certifications

- Quantities flexibility

- Reputation

INDUSTRIALISATION : INDUSTRIALISE YOUR PRODUCT

- When designing a formulation, we always start to think about the industrial process to ensure its scalability. We follow a specific industrialisation pathway which has proven efficiency through

- Pilot manufacturing : We ensure an intermediate upscale in our facility in Annecy to finetune manufacturing parameters

- Development manufacturing : We ensure the integration of the manufacturing in your facility or at the CMO, and follows until the operators master the process until the validation.

- Know how transmission : We provide theoretical transmission through learning modules to engineers and operators and operational transmission through hands on approach in clean room during development manufacturing.

PROCESS & SITE OPTIMISATION : OPTIMISE MANUFACTURING EFFICIENCY

Through our extensive industrial experience, we perform industrial audits

Identification of the gaps / improvement areas

- Manufacturing documents

- Manufacturing site organisation (clean rooms, flows,…)

- Equipment in place

- Manufacturing process

- Operators’ manipulations

Optimisation advices

- Robustness / batch-to-batch consistency and repeatability

- Yield

- Capacity / Scale-up

- Ergonomics

Equipment design & manufacturing

For all synthesis steps, we design and manufacture through our affiliated company Vortex, customised industrial equipment tailored to your needs.

PROCESS AUTOMATISATION : AUTOMATISE YOUR PROCESS

We have developed a unique expertise on the full automatization of the synthesis steps (from solubilisation of raw materials until obtaining a bulk gel ready to fill in syringes).

We have the capacity to automatise existing complex processes by respecting the manufacturing flowchart.

The advantages of automatising synthesis steps:

- Reduce gel losses during process

- Improve batch-to-batch repeatability

- Increase the manufacturing capacity without clean room extension (only a few squared meters)

- Reduce the number of operators

- Keep process confidentiality

INDUSTRIALIZATION : EQUIPMENT

WE ACCOMPANY OUR CUSTOMERS WITH THE OBJECTIVE TO OPTIMISE INDUSTRIAL OPERATIONS, TO INCREASE MANUFACTURING CAPACITY, PROCESS YIELD AND PROCESS ROBUSTNESS THANKS TO OUR RECENT ACQUISITION OF VORTEX, A LEADING EXPERT IN CUSTOMIZED INDUSTRIAL EQUIPMENT.

- Equipment audit: equipment review, equipment evaluation;

- Equipment recommendations: Definition of equipment needs according to commercial & industrial plans, recommendation of equipment references and equipment manufacturers;

- Equipment Design & Development: customized equipment integrated in your process, full automatization of all the synthesis steps (from solubilization to a bulk gel ready to be filled in syringes up to 25-30L batches).

MARKETING

WE SUPPORT IN VARIOUS MARKETING ACTIVITIES THROUGH YOUR PRODUCT’S LIFECYCLE:

- Strategic Insights : We take part to Advisory Boards to draw market trends, share market knowledge

- Competitive Screening : We can perform an independent evaluation of the competitive products, both on their properties but also on their positioning.

- Strategic Marketing : We support in the preparation of marketing plans, product management, positioning strategy.

- Operational Marketing : We support launch plans and activities, marketing tools, sales support creation, events management, team training and building.

- Marketing audit : We review your marketing activities and tools and provide recommendations.

CORPORATE SUPPORT SERVICES

WE GUIDE OUR CLIENTS AND PROVIDE STRATEGIC SUPPORT TO FACILITATE MARKET ENTRY AND ACCELERATE GROWTH THROUGH DUE DILIGENCE, LICENSING, AND STRATEGIC ANALYSIS.

M&A DUE DILIGENCES : ACQUIRE OR SELL A BUSINESS

We provide technological & strategic due diligence for acquirers (BA, VC, PE, Family offices) and to sellers (entrepreneurs) ahead of a transaction closing. We perform onsite due diligences and provide you with a report (red flag or detailed) with recommendations, and eventual future investments estimations.

- Marketing : Positioning in its market, portfolio analysis, competitivity

- Manufacturing : Manufacturing site, Equipment, Process, Formulation / Technology

« FAST-TRACK » HYALURONAN TRAINIG : MAKE YOUR TEAM OPERATIONAL QUICKLY

We provide a fast-track training to new managers and leaders (C-levels, top management) entering in the hyaluronan industry, to enable a faster on-boarding. The Fast Track Hyaluronan Training aims to provide them with essential and comprehensive knowledge of hyaluronan.

THE « HA INCUBATOR » ACTIVITY ENABLES US TO INNOVATE AND/OR SUPPORT INNOVATION MAINLY IN HYALURONIC ACID.

THIS INCLUDES OUR FIRST TWO STARTUPS, NOXELIS AND LEDVARD, WHICH ARE RESPECTIVELY ACTIVE IN OPHTALMOLOGY AND SPORTS MEDICINE.

NOXELIS is a French company specializing in ophthalmic medical devices, based in Annecy, dedicated to the development of next-generation treatments containing polymers and Hyaluronic Acid. Through its technological platform, Noxelis offers various innovative formulations to treat ocular surface diseases.

Founded by a team of passionate experts, Noxelis is committed to bringing innovative technologies to market with a single goal: to enhance the ocular comfort of patients suffering from dry eye.

LEVARD is a French company located near Annecy, dedicated to designing products that enhance the physical health of athletes, enabling them to perform confidently and providing support in their athletic endeavors.

At Ledvard, we believe that muscle power is not beneficial if mobility and joint function are restricted.

We leverage our scientific expertise to enhance your performance.

THE « HA INCUBATOR » ACTIVITY ENABLES US TO INNOVATE AND/OR SUPPORT INNOVATION MAINLY IN HYALURONIC ACID.

THIS INCLUDES OUR FIRST TWO STARTUPS, NOXELIS AND LEDVARD, WHICH ARE RESPECTIVELY ACTIVE IN OPHTALMOLOGY AND SPORTS MEDICINE.

NOXELIS is a French company specializing in ophthalmic medical devices, based in Annecy, dedicated to the development of next-generation treatments containing polymers and Hyaluronic Acid. Through its technological platform, Noxelis offers various innovative formulations to treat ocular surface diseases.

Founded by a team of passionate experts, Noxelis is committed to bringing innovative technologies to market with a single goal: to enhance the ocular comfort of patients suffering from dry eye.

LEVARD is a French company located near Annecy, dedicated to designing products that enhance the physical health of athletes, enabling them to perform confidently and providing support in their athletic endeavors.

At Ledvard, we believe that muscle power is not beneficial if mobility and joint function are restricted.

We leverage our scientific expertise to enhance your performance.

THE « HA INCUBATOR » ACTIVITY ENABLES US TO INNOVATE AND/OR SUPPORT INNOVATION MAINLY IN HYALURONIC ACID.

THIS INCLUDES OUR FIRST TWO STARTUPS, NOXELIS AND LEDVARD, WHICH ARE RESPECTIVELY ACTIVE IN OPHTALMOLOGY AND SPORTS MEDICINE.

NOXELIS is a French company specializing in ophthalmic medical devices, based in Annecy, dedicated to the development of next-generation treatments containing polymers and Hyaluronic Acid. Through its technological platform, Noxelis offers various innovative formulations to treat ocular surface diseases.

Founded by a team of passionate experts, Noxelis is committed to bringing innovative technologies to market with a single goal: to enhance the ocular comfort of patients suffering from dry eye.

LEVARD is a French company located near Annecy, dedicated to designing products that enhance the physical health of athletes, enabling them to perform confidently and providing support in their athletic endeavors.

At Ledvard, we believe that muscle power is not beneficial if mobility and joint function are restricted.

We leverage our scientific expertise to enhance your performance.

OUR FACILITIES

2 facilities are located in the French Alps:

Hyaluronan services

Falgagen offices and laboratory are located in Allonzier (Annecy, France)

- All manufacturing steps are carried out in lab conditions until obtaining a sterile syringe

- Volume capacity from 0 to 5’000 ml of gel / solution.

- Fully equipped with maintained and calibrated analytical equipment

- ISO 5 laminar flow for PoC / preclinical batches

- Falgagen rents a clean room to a partner for batch production under clean conditions

Equipment development

Vortex conception & workshop are located in Meyzieu (Lyon, France)

- Conception team and workshop are in the same building to ensure efficient communication

- Laboratory available for intermediate testing on equipment parts

- FAT room available for final delivery testing of the finished equipment.

OUR AVAILABLE INOVATION

We have worked on various advanced technologies which are available for out-licensing.

FAL-01 “GAÏA”

- Injectable formulation

- European patent granted in five major countries

- Formulation patent of crosslinked Hyaluronan combined with Zinc and Zinc derivatives.

- Available for use in the aesthetics dermatology.

- Potential positioning as innovative dermal fillers targeting a skin-tensing effect.

FAL-02 “INUI”

- 2 products (topical and drinkable solutions)

- Highly concentrated serum and drink for an innovative “In&Out” approach.

- Available for use in cosmetics, and aesthetics.

- Potential positioning as innovative dermocosmetics targeting anti-aging effects and skin quality.

OUR TEAM

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

LET US KNOW

HOW WE CAN

HELP YOU

Email: contact@falgagen.com

FALGAGEN

83 Impasse de la Fruitière

74350 Allonzier-la-Caille

FRANCE